It is important to understand that:

1--Insulation is needed to keep conditioned areas separated from unconditioned areas.

2--The building envelope is made up of two barriers: (1) the air-barrier (2) the insulation-barrier

To protect against rain (or moisture) penetration from the outside wall, a continuous vapor barrier should be installed within the wall system. In other words, have a well-functioning drain system between the inside and outside wall. Also have a sill gasket on top of the foundation wall to prevent moisture from wicking into the framed wall from the concrete foundation (via capillary action).

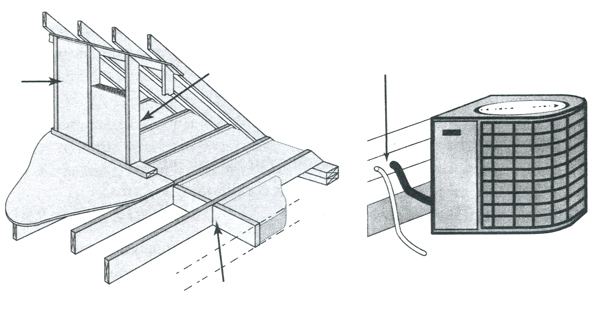

Air sealing prevents moist air from entering the wall. Leakage can be found in dropped ceilings, kitchen soffits, ductwork, attic access, pull-down stairs, recessed light fixtures, attic-to-kneewall transitions, etc.

Materials that can be used are: caulk, spray foam, gaskets, housewrap, sheet metal, weather-stripping, Mastic (I prefer tape over putty--do not use duct tape on ducts!)

Fiberglass, the most common insulation, does not stop air leakage. However, several types of dense-packed cellulose and some foams can effectively reduce air flow as well as heat-flow.

Types of insulation: Insulation falls into four conventional categories with specific uses:

• Loose Fill

Fiberglass, Cellulose, Mineral Wool.

(Typically used in attics, between roof rafters, in wall cavities in wood-frame homes, and in floors between floor joists.)

• Blankets

Fiberglass, Mineral Wool

(Rolls and batts)

• Rigid Foam

Expanded polystyrene (EPS), Extruded Polystyrene (XPS), and Polyisocyanurate (Usually applied externally, i.e. on roof decking, external sheathing, or foundations, but could be used in wall cavities or as structural insulation panels, sandwiched between 2 sheets of oriented strand-board 2-12 inches thick).

• Liquid Foam

(Used in wall cavities or to seal air gaps in the building envelope, that is, the walls and roof).

• Another option is "Natural" Insulation

In order to keep the moisture away from the insulation use a "vapor wrap."

___________________

Fiberglass (Loose Fill and Blankets)

• Inexpensive and effective.

• Standard fiberglass insulation is made with a formaldehyde-based binding agent - a cancer causing agent.

Pros: It doesn't shrink, won't burn, and is non-nutritive to insects. Environmentally and people-friendly products are now available i.e. Miraflex (by Owens-Corning) which requires no formaldehyde binders. It has greater tensile strength than standard fiberglass insulation. As a result, they don't break off and become airborne as readily as those found in standard fiberglass. It therefore, protects workers from inhaling fibers.

Cons: microscopic slivers may become dislodged during handling and can be inhaled by workers. Fiberglass blankets do not seal wall and ceiling cavities very tightly. Unless an installer is using encapsulated batts, a vapor barrier is required to create an airtight envelope to protect the insulation from moisture. Fiberglass settles and sags, resulting in a decline in R-value over time. --------------

___________________

Cellulose (Recycled Newspaper and Shredded Cardboard)

• Best choices environmentally

• Absorbs moisture which can cause cellulose to mold and rot.

• May settle and sag, creating air spaces. (R-value)

• Cheaper to purchase but installation costs may be higher than for fiberglass batts.

___________________

Spray Foam Insulation 1

A product commonly used in the 70s and 80s was urea formaldehyde. It filled cavities un-evenly, resulting in cold spots, but also caused serious health problems. Polyurethane was also used, but it used CFC-11 as blowing agent, an ozone-destroying chemical.

Polyurethane foam manufacturers have now eliminated formaldehyde and substituted carbon dioxide gas for the ozone-depleting blowing agents.

The following products are worth considering:

___________________

Spray Foam Insulation 2

• Icynene (a liquid dissolved in water) is one of the leading alternatives to polyurethane, is sprayed in a paint-thin layer into open wall, adheres firmly and expands to approximately 100 times its original volume. Excess is trimmed off with a handsaw.

• Icynene provides about R-3.6 per inch. It creates an airtight seal that reduces air filtration. It is resistant to water vapor thus eliminating the need for vapor barriers.

• Icynene does not settle, sag, or shrink. It has a stable R-value.

• Icynene production uses no CFCs or HCFCs and does not outgas harmful chemicals and offers no nutritive value to termites.

• Although Icynene is usually sprayed on, it can be poured into the cavity through a small opening in the wall. The product then expands from the bottom up, filling the voids, providing R-4 insulation per inch.

Other environmentally friendly products are:

• A foam called "SuperGreen," a polyurethane product that contains a hydrofluorocarbon (HFC) expanding agent which contains no chlorine atoms, thus does not deplete the ozone layer.

• Air Krete is an inorganic substance containing magnesium oxide. It is stable and does not shrink or settle after being applied. It supplies about R-3.9 per inch.

• All foam must be applied by trained applicators.

___________________

Rigid-Foam Insulation

Used for foundations, slabs, and in SIPs (Structural Insulated Panels)

Rigid foam insulation products have a higher R-value per inch than blankets or loose fill materials.

Rigid foam insulation comes in three varieties:

• (1) expanded polystyrene(EPS)

• (2) extruded polystyrene (XPS)

• (3) polyisocyanurate.

___________________

Rigid-Foam Insulation

(for foundations and slabs)

Polyisocyanurate (polyiso)

• Polyiso is the least environmentally friendly foam board insulation. It is a closed-cell foam made with an HCFC blowing agent. Although it does less damage to the stratospheric ozone layer than the compound it replaced, HCFC-141b is the worst of the new generation blowing agents.

• Polyiso offers the highest R-value (R-6.5 and R-8 per inch).

• Polyiso is manufactured with various facings, for example, plastic or aluminum, which further increases its resistance to heat.

• Polyiso suffers from a gradual deterioration of R-value over time.

No matter what type of foam you use, be sure to protect it from direct sunlight, because ultraviolet radiation damages foam insulation products.

___________________

Rigid-Foam Insulation

(for foundations and slabs)

Expanded polystyrene (EPS),

• The most environmentally friendly option, EPS is not made using ozone-depleting chemicals and is a closed-cell insulation material (known for coffee cups and packing beads).

• EPS is made from polystyrene beads mixed with liquid pentane (a hydrocarbon "blowing agent") making it expand to form millions of tiny bubbles. The pentane diffuses for 95% out of the foam and is replaced with air.

• It is brittle and is therefore not recommended for underground use.

• If used underground, some form of moisture barrier may be required, especially when using around foundations.

___________________

Rigid-Foam Insulation

(for foundations and slabs)

Extruded polystyrene (XPS)

• XPS is a closed-cell insulation board known as blue board, (but also comes in pink).

• XPS is made from polystyrene and a hydrochlorofluorocarbon (HCFC) blowing agent. Although HCFCs are the much less damaging to the ozone layer than their predecessors, the chlorofluorocarbons (CFCs), the new-generation blowing agents do break down in the atmosphere when exposed to sunlight, releasing chlorine atoms that react with ozone in the stratosphere

• XPS not only damages the ozone layer, it costs a little more than EPS foam. It does, however, have a slightly higher R-value (R-5 per inch) than expanded polystyrene.

• XPS tends to be more consistent in density throughout, has a higher compressive strength than EPS, and is much more resistant to moisture.

___________________

Natural Insulation

Sheep's Wool

• Wool has a high R-value and

• Wool is produced naturally with virtually no fossil-fuel energy.

• Wool insulates when wet.

• Wool is naturally flame resistant.

Cotton (Comes in batts and loose fill)

•Cotton has the same R-value per inch as cellulose insulation.

•Cotton production is one of the most chemically intensive and environmentally harmful areas of agriculture. Soils are sprayed with herbicide to control weeds and crops are sprayed with insecticides to kill insects.

Straw

• Straw bales provide a high levels of insulation and are inexpensive.

• Bales are heavy and difficult to install. Additional framing adds to the cost of a home.

• Loose straw ceiling insulation is lighter than bales and thus reduces the need to fortify roof framing. o Loose straw doesn't provide as much insulation as baled straw and poses a much greater fire hazard than intact bales.

• Straw-clay is made by mixing loose straw and a watery solution of pure clay and dirt, packed into wall forms and left to dry. The result creates a thick, insulated wall. The clay protects against fire and retards mildew and mold growth.

For more info on "Wall insulation", "Air Sealing Checklist", Ductwork or Blower-door test.