Cities use tremendous amounts of energy.

Cities use tremendous amounts of energy. Therefore there is great opportunity to redesign, reconfigure the way to reduce (energy) waste, and increase (energy)efficiency.

Cities use tremendous amounts of energy.

Cities use tremendous amounts of energy.

Therefore there is great opportunity to redesign, reconfigure the way to reduce (energy) waste, and increase (energy)efficiency.

Most cities have, especially in the USA, an abundance of waste and are short in landfill space.

The obvious solution is to convert this waste into energy.

Several cities and districts in the US and many around the world are doing just that.

A few examples I’ll briefly describe here are Fairfax County, VA. andDelaware County, PA…. Where waste is converted in energy (with or without autoclave, in where the waste is heated to 150 F to pulverize the material, except metals, before it gets to the burners), the RWE plant in Werne, Germany that since 2000 has added burning household waste in the same boiler as they burn coal, to create energy and in the process produces Gypsum and road-cover material, and the ABB plant in Zurich, Swiss.

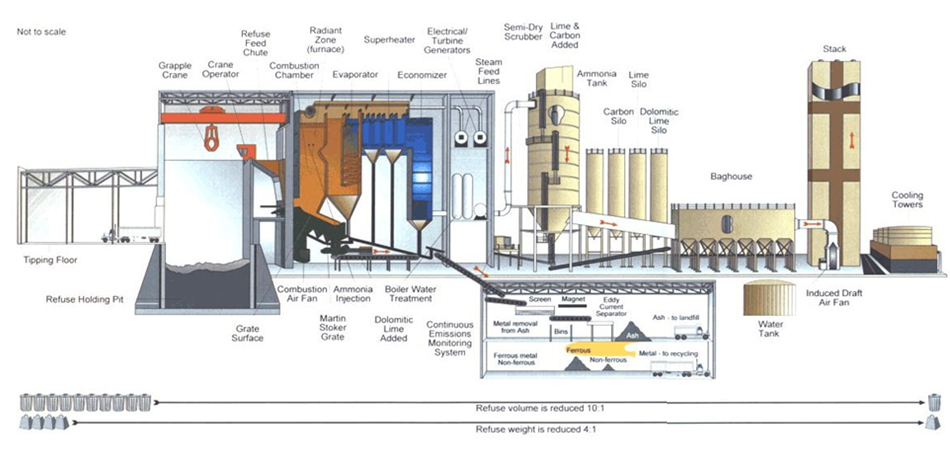

In the Fairfax County plant in Fairfax County, VA.the trash is burned on a grate at 2,400°F, to produce steam for the turbine-generator, to generate electricity a regular steam generation plant.

In the Fairfax County plant in Fairfax County, VA.the trash is burned on a grate at 2,400°F, to produce steam for the turbine-generator, to generate electricity a regular steam generation plant.

The ash from the incinerated trash is sifted for ferrous and nonferrous metals, which are recycled. Only about 25% of the original weight of the trash goes to the landfill. The volume of trash is reduced by 90%, the remaining 10% ends up back at the Landfill.

Nearly 350 methane extraction system wells are used to collect landfill gas. The gas is used to generate electricity on site, to heat workspaces, or is sent to a Pollution Control Plant where it is used in the sludge combustion process.

Click for larger drawing

The plant generates 79 megawatts of electricity, enough to power about 75,000 homes. Covanta sells the electricity to Virginia Dominion Power, and Fairfax County receives a portion of the revenue.

For more info: http://www.fairfaxcounty.gov/dpwes/trash/dispomsf.htm

Delaware co plant:

The Energy-from-Waste Facility in Delaware Valley, Chester, PA opened in 1992 and is another Covanta plant similar in many ways to the Fairfax county plant. The plant processes up to 3,348 tons of municipal and commercial solid waste each day.It generates approximately 80 megawatts of electricity, 90 percent of which is sold to the local utility.

Air Quality Control: 6 dry scrubbers followed by 6 fabric filter (baghouse) systems. Secondary Materials Recovery: Recovery of ferrous (steel) and non-ferrous (aluminum) metals.

The floor is vast - 31/2 acres - heaped with refuse two stories high. Six boilers combust up to 3,348 tons of municipal solid waste per day, turning water into steam that drives a turbine generator that makes enough electricity for 75,000 households. The plants produce 9 million megawatt-hours of electricity a year.

It burns waste 24/7. It accepts all of Delaware County's trash, about 400,000 tons a year, and about 300,000 tons from Philadelphia.

Energy-from-Waste (EfW) facilities offer a safe, technologically advanced means of waste disposal while also generating clean, renewable energy, reducing greenhouse gas emissions and supporting recycling through the recovery of metals.

For more information click any of these links:

http://www.covantaenergy.com/facilities/facility-by-location/delaware-valley.aspx

( http://www.encyclopedia.com/topic/Covanta_Energy_Corp.aspx )

link to trash-into-power-generating article:

http://azdailysun.com/business/energy/turning-trash-into-power-generating-treasure/article_718e17e4-1753-5672-8a5f-0b1fd597400b.html

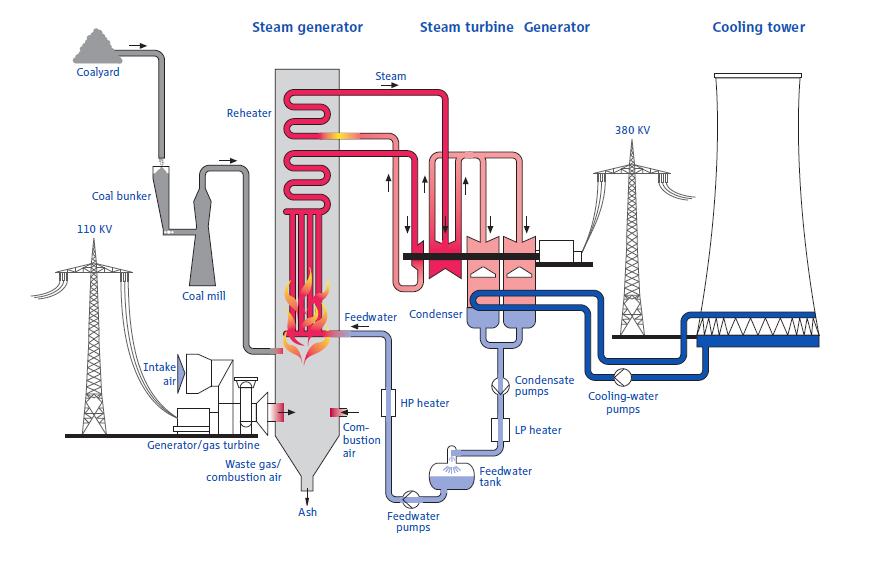

InWerne, GermanyElectric power generation, is fueled by coal waste. It is seen as a more environmentally responsible form of production, because it uses waste dust and also results in clearing spoil sites that can be later used for industrial redevelopment.

InWerne, GermanyElectric power generation, is fueled by coal waste. It is seen as a more environmentally responsible form of production, because it uses waste dust and also results in clearing spoil sites that can be later used for industrial redevelopment.

Dust particles receive a negative charge thus are magnetically attracted by positive electrodes, designed as plates. The rapping gear's periodic hammering knocks off the dust, which falls into a funnel and is collected. It is re-fed into the furnace in doses. The electrostatic precipitators retain over 99% of all dust.

In a continuous rain of milk of lime, over 90 % of the sulpher dioxide is scrubbed from the flue gas. A chemical reaction generates a new material, gypsum, which is used as construction material. Every year, 60,000 tons of gypsum is produced.

In 2001 a secondary fuelwas added, which is made up of treated, cleaned and shredded municipal and industrial waste, such as carpet remnants, textiles,waste plastics, and packaging materialprocessed in special plants. A different designed burner was added to handle the shredded material to burn directly in the same boiler.

The already very efficient coal plant will use a maximum of 10 percent “replacement fuels” to replace imported coal, which will contribute to the conservation of resources aswell and reduce CO emissions.

More:http://www.rwe.com/web/cms/contentblob/77508/data/10069/Werne-Gersteinwerk-power-plants-pdf.pdf

The company, ABB is supplying a complete power and automation solution for a new waste-to-energy power plant – the largest of its kind in Germany - that will generate clean heat and power for one of the biggest chemical and pharmaceutical parks in Europe. More at: http://www.automation.com/content/abb-controls-waste-to-energy-power-plant-in-germany

Another interesting use of waste to make energy: Turning pig poop into energy.

Loyd Ray Farms is an anaerobic-digestion waste handling system that Turns pig poop into energy.

This pilot project turns methane gas from hog waste into enough electricity to power 35 homes for a year. It also prevents the release of greenhouse gases equivalent to nearly 5,000 metric tons of CO2 per year, which is like taking 900 cars off the road.

Google will use a portion of the avoided emissions from the system, owned by NC Duke University, to fill Google’s carbon-offset portfolio and meet its carbon neutrality goal.

For more information about the project, please visit The Duke Carbon Offsets Initiative website at:

http://sustainability.duke.edu/carbon_offsets/Projects/loydray.html

or:

http://googlegreenblog.blogspot.com/2011/09/sometimes-greening-google-means-getting.html

or this news article:

http://www.yadkinripple.com/view/full_story/16182620/article-Google-and-Duke-turn-pig-poop-into-energy?instance=home_news_lead

Just recently received a note about a very interesting film clip: http://www.youtube.com/watch?v=CWf9nYbm3ac&feature=related