A solar cell or photovoltaic cell is a device that converts solar

energy into electricity by the photovoltaic effect. Assemblies of cells are used

to make solar modules, which may in turn be linked in photovoltaic arrays.

Solar cells are expected to be capable of producing electricity for at least twenty

years without a significant decrease in efficiency.

Solar cells are manufactured primarily in Japan, China, Germany, Taiwan and the

USA, although many other nations have gained significant solar cell production

capacity.

Photovoltaic Systems are relatively simple in design, have no moving parts, and

need little maintenance. Once the parts are purchased and installed, solar power

costs nothing.

When solar manufacturers and installers talk about costs, they usually speak in

terms of dollars per installed watt.

PV systems may be designed to provide any amount of power depending on the specific

needs of the homeowner and depending on how much the homeowner is willing to invest

at that time. Think about PV power as an investment in energy security and environmental

responsibility, as opposed to being purely financially beneficial. By owning a

PV array and generating clean electricity, one becomes part of the energy movement

and gains some independence from the price fluctuations and negative impacts of

fossil fuels.

A major benefit of solar power is the ability to easily expand a system's size

and increase the amount of energy being produced. A solar panel will generate

a minimum of four times the amount of energy used in its production.

Because the fossil fuel industry receives an estimated $15 billion each year in

federal government subsidies, the solar industry currently has a tough time competing.

However, fossil fuels may be depleted within 40 years, and the solar energy industry

is currently growing at a rate of 25% per year. With the rising cost of energy,

solar energy is steadily gaining popularity, especially since more and more states

and electrical companies pay for more power than gets fed into the grid. The homeowner

may be able to be paid for this excess power by the power company or other incentive

program. Likewise, during times when the array is not producing enough power for

the home, the homeowner can buy the difference needed from the grid. The process

is seamless and automatic.

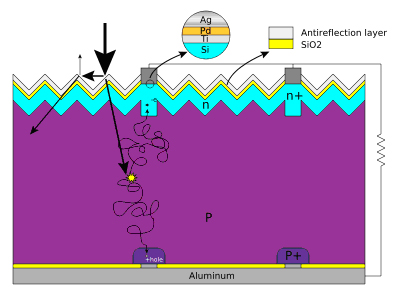

Solar cells are often electrically connected and encapsulated as a module.

PV modules often have a sheet of glass on the front (sun up) side, allowing light

to pass while protecting the semiconductor wafers from the elements (rain, hail,

etc.). Solar cells are also usually connected in series in modules, creating an

additive voltage. Connecting cells in parallel will yield a higher current. Modules

are then interconnected, in series or parallel, or both, to create an array with the desired peak DC voltage and current.